Transparent

Colorless Parts

Superior

Surface

Quality

High Detail

Precision

Complex

Geometries

Dimensional

Consistency

Somos®WaterShed is an equivalent solution for material needs

such as ABS and PBT. The clear resin is optically approved.

It helps shorten the product development and testing process.

With these features, Somos®WaterShed; in areas such as

automotive, aerospace and consumer electronics; it is frequently

preferred in applications such as precision casting models.

What is SLA

(Stereolithography)?

The best solution for

precise dimensions and

smoot surface quality

In SLA printing technology, the photopolymer resin

is cured with a UV laser source. This technology requires

support structures which are removed after printing.

It is a frequently preferred printing technology for parts

which need high accuracy and smooth surface quality.

SLA parts can be finished a very high standard using

a variety of post-processing methods such as sanding,

painting and varnishing.

Advantages of

SLA 3D Printing

Dimensional

Consistency

Somos ®

Watershed

Somos®WaterShed is an equivalent solution

for material needs such as ABS and PBT.

The clear resin is optically approved.

It helps shorten the product development

and testing process. With these features,

Somos®WaterShed; in areas such as automotive,

aerospace and consumer electronics; it is

frequently preferred in applications such as

precision casting models.

What is SLA

(Stereolithography)?

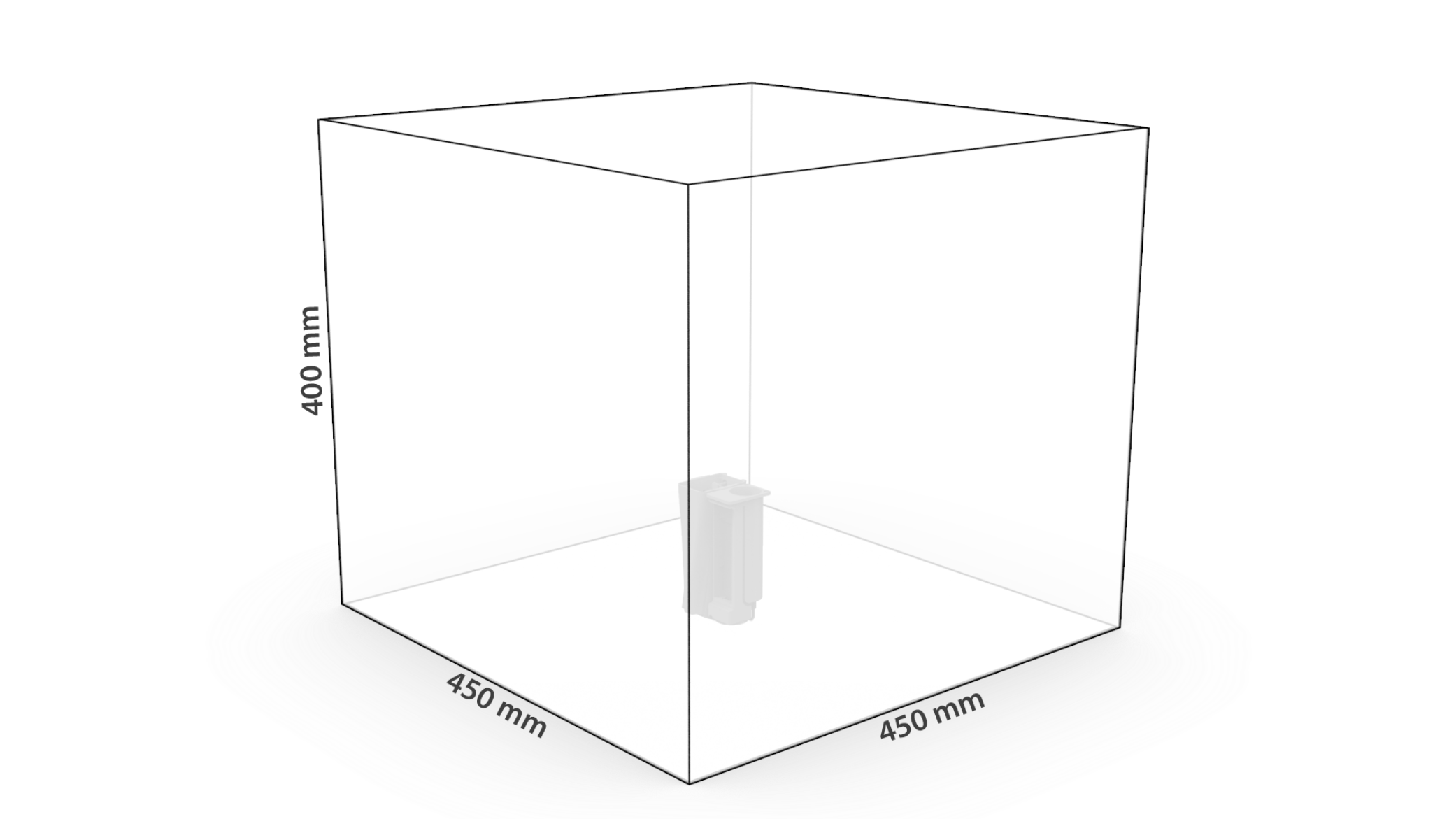

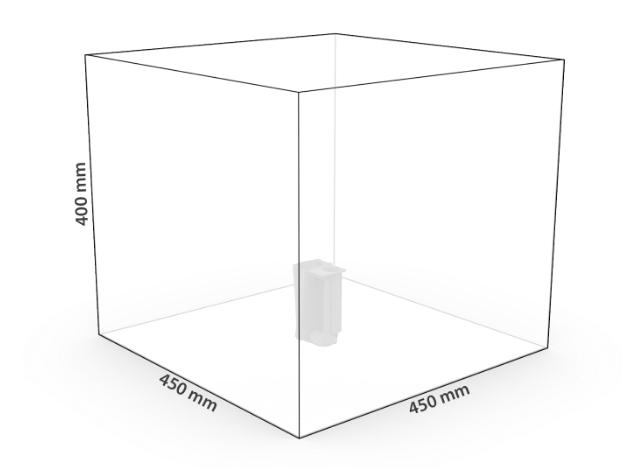

Technical

Specifications

In SLA printing technology,

the photopolymer resin is cured with

a UV laser source. This technology requires

support structures which are removed after printing.

It is a frequently preferred printing

technology for parts which need high

accuracy and smooth surface quality.

SLA parts can be finished a very high

standard using a variety of post-processing

methods such as sanding, painting

and varnishing.

The best solution for

precise dimensions

and smooth surface quality

Transparent

Colorless Parts

Superior

Surface Quality

High Detail

Precision

Complex

Geometries