Applications

Carbon Fiber Reinforced Polyamide

Glass Fiber Reinforced Polyamide

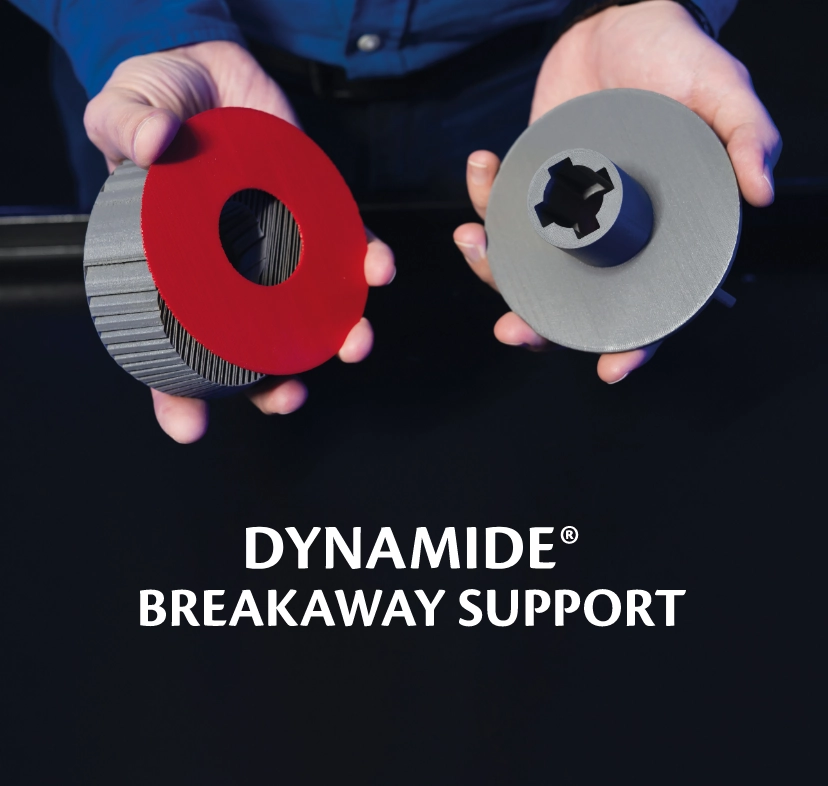

Strong, durable filaments with high thermal resistance

for effortless printing of end-use parts,

functional prototypes and low volume manufacturing

Functional End-Use Parts

Open Material System

Unparalleled Surface Quality

Key to exceeding standards by

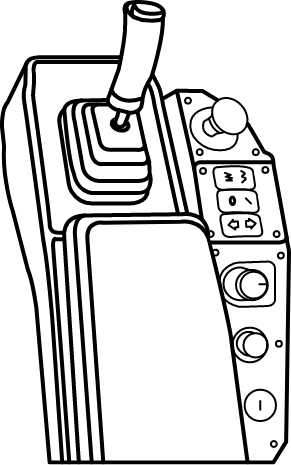

LOOP PRO X+ is a dedicated

material blend connected to

software and hardware

working in a perfect harmony.

High-end composite materials

with high thermal resistance

allow to print strong and durable

end-use parts and models.

Use LOOP PRO X+ dedicated

DYNAMIDE ® materials or create

your own presets for third party

filaments with open parameters

that can be changed in

LOOP 3D CLOUD 2.0 software.

LET’S TALK

Request a Quote

Mechanical Properties

Physical Properties

Mechanical Properties

Physical Properties

Mechanical Properties

Physical Properties

Strong, durable

filaments with high

thermal resistance

for effortless printing

of end-use parts,

functional prototypes

and low volume

manufacturing.

Open

Material System

Use LOOP PRO X dedicated

DYNAMIDE ® materials or create

your own presets for third party

filaments with open parameters

that can be changed in LOOP 3D

CLOUD 2.0 software.

Unparalleled

Surface Quality

Key to exceeding standards

by LOOP PRO X is a dedicated

material blend connected to

software and hardware working in

a perfect harmony.

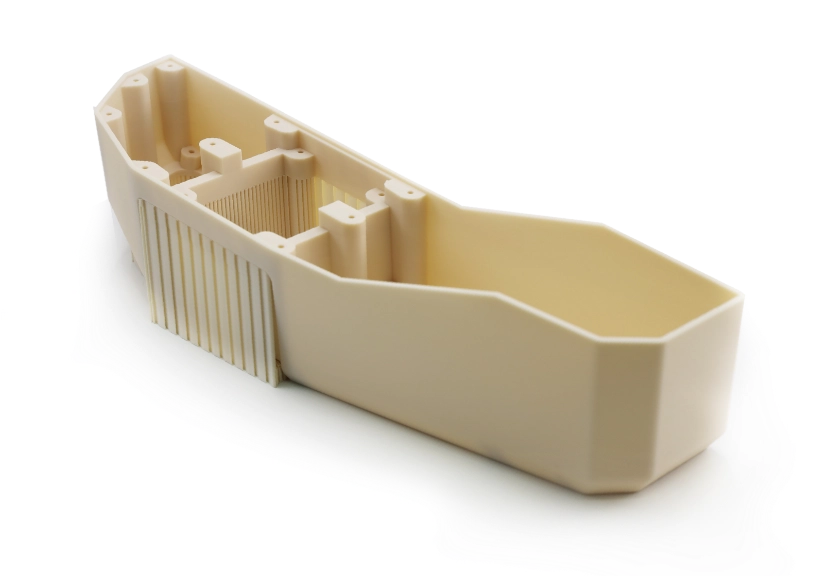

Functional

End-Use Parts

High-end composite materials

with high thermal resistance allow

to print strong and durable end-use

parts and models.

Carbon Fiber

Reinforced Polyamide

Glass Fiber

Reinforced Polyamide

Density

Density

Physical Properties

Physical Properties

Test Method

Test Method

Property

Property

DSC, 10 0 C

220 0 C, 10 k

Melting Temperature

Melt Index

ASTM D792

ASTM D792

ISO 75 1.8 MPa

ASTM 1525

Heat Deflection Temperature

Vicat Softening Temperature

ISO 75 0.45 MPa

DSC, 10 0 C / min

Heat Deflection Temperature

Glass Transition Temperature

Mechanical Properties

Mechanical Properties

ASTM D638

ASTM D638

Tensile Strength

Tensile Strength

85 MPa

47.8 MPa

135 MPa

72.9 MPa

ASTM D790

ASTM D790

Flexural Strength

Bending Strength

3.5%

6.8 %

1.7 %

ASTM D638

ASTM D638

Elongation at Break

Elongation at Break

Property

Property

Test Method

Test Method

X-Y Axis

X-Y Axis

Value

Value

215 0 C

25 (g/10 min)

1.2 (g/cm 3 )

1.1 (g/cm 3 )

122 0 C

104.8 0 C

190 0 C

97.5 0 C

61.5 MPa

30 MPa

2.8%

Physical Properties

Mechanical Properties

Density

Test Method

Property

DSC, 10 0 C

Melting Temperature

ASTM D792

ISO 75 1.8 MPa

Heat Deflection Temperature

ISO 75 0.45 MPa

Heat Deflection Temperature

Value

219 0 C

1.17 (g/cm 3 )

195 0 C

214 0 C

ASTM D638

Tensile Strength

105 MPa

165 MPa

ASTM D790

Flexural Strength

3%

ASTM D638

Elongation at Break

Property

Test Method

X-Y Axis

66 MPa

3%

Z Axis

Z Axis

Z Axis