Effortless support removal with

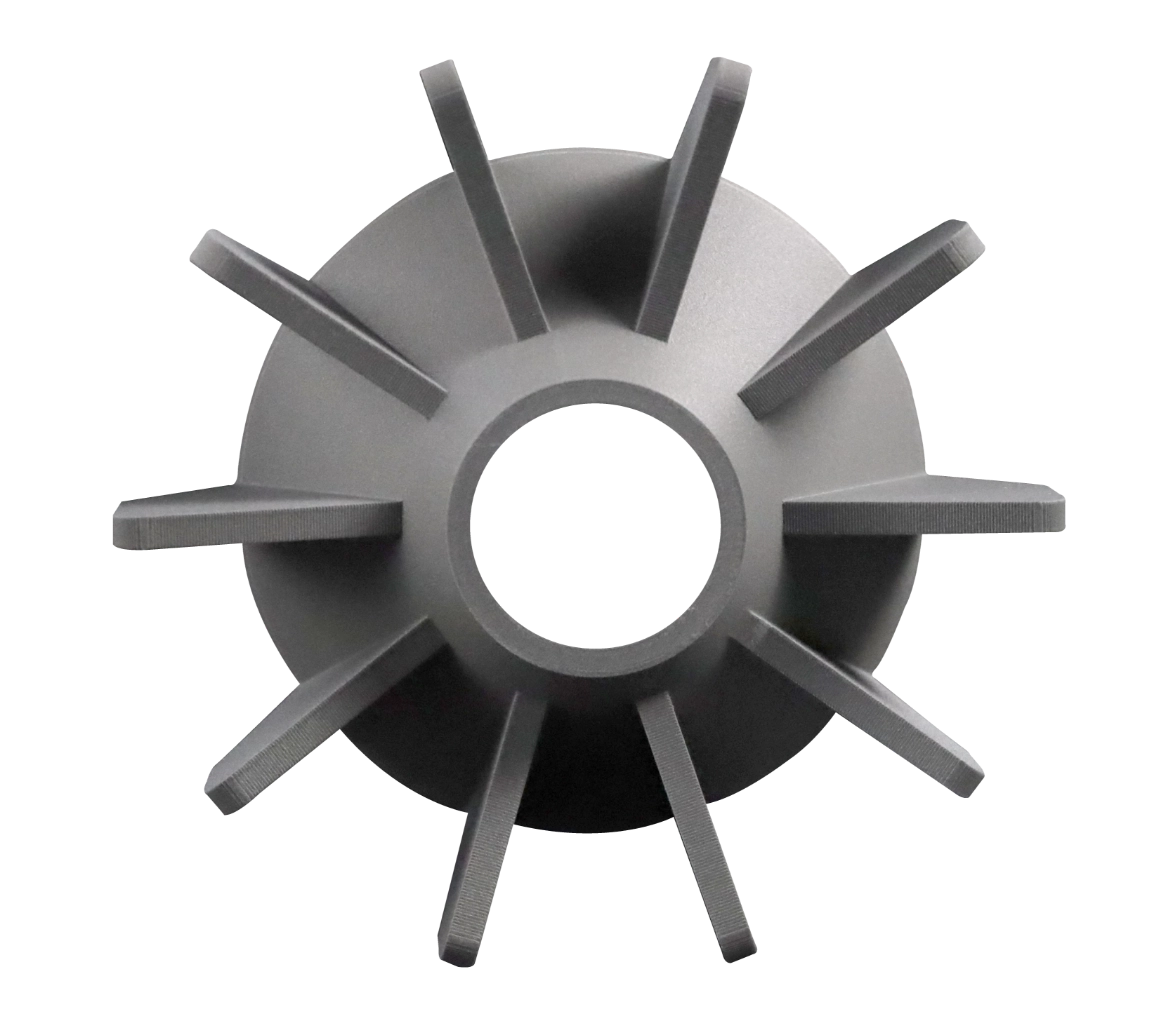

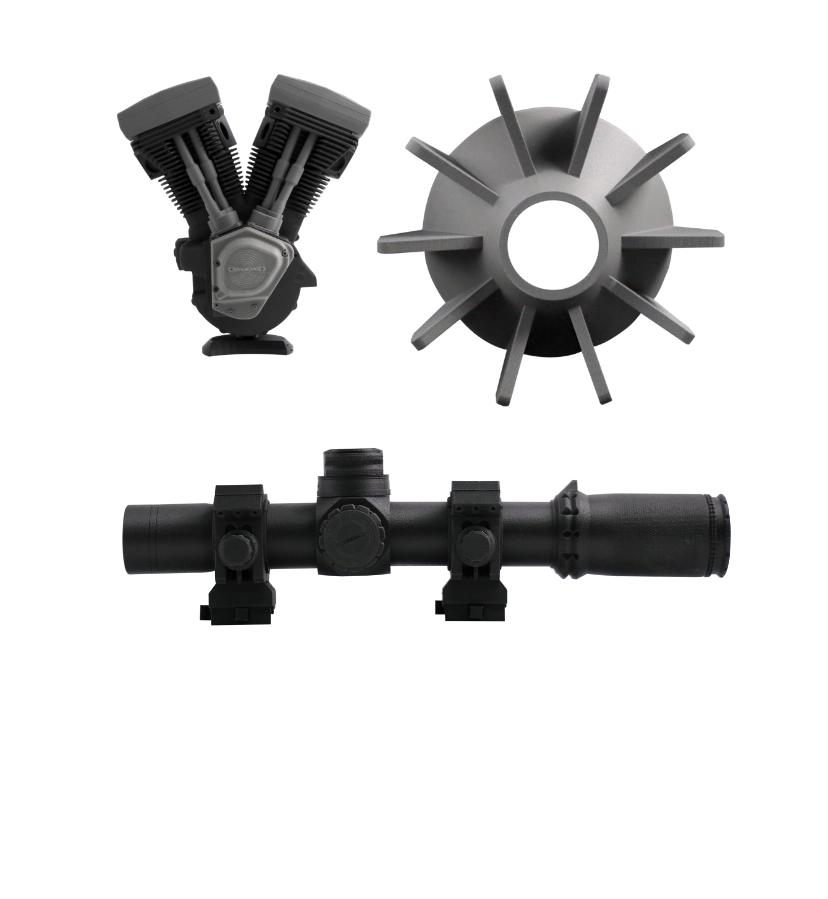

DYNAMIDE ® industrial-grade composite filaments allow you to print durable

end-use parts that can withstand very

high temperatures where many other

materials will yield around halfway.

The 3D printed models are highly

accurate, functional and look exceptional.

Made with high-quality components,

LOOP PRO X 3D Printer enables you to

use high-end technology at a fraction

of the cost with the highest price

performance ratio. No surprises,

no hidden charges.

Build volume of 500 x 350 x 500 mm

allows printing large models in one piece

and low-volume multi-production.

CNC Milled Unibody

Aluminum Casting

Modular electronic components are designed to

minimize the damage of potential issues without creating

the need for on-site technical service.

Combination of CNC-milled unibody aluminum

casting and specially engineered mechatronics

ensures high rigidity, minimal vibration, outstanding

dimensional accuracy and unparalleled surface quality.

Ambient

Led Light

Flexible

Build Plate

Automated

Filament Changeover

When the printing process starts,

the LED lights turn on until the printing

is finished. These lights let the user know

that the printer is currently in use,

making it easy to check the machine’s

status at a glance

Get consistent results with magnetic

spring steel sheet and PEI film to firmly

embed the model on the surface and

remove it fast when the job is done.

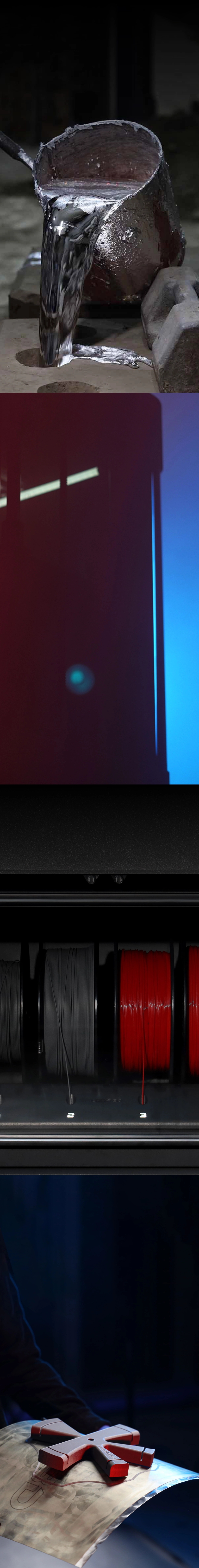

Effortless support

removal with

game-changing

surface quality

Made with high-quality components,

LOOP PRO X 3D Printer enables you to use high-end technology at a fraction of the cost with the highest price-performance ratio. No surprises, no hidden charges.

We offer hassle-free operation for all with a modular design that provides easier maintenance and reduces downtimes. Maintain the quality and mechanical properties of 3D printed models exceeding quality standards.

Build volume of 500 x 350 x 500 mm allows printing large models in one piece and low-volume multi-production.

Functional Parts

Affordable Price & Low Running Cost

Plug & Play Maintenance

Large Build Volume

Unibody

Aluminum Casting

Ambient

Led Light

Automated

Filament

Changeover

High rigidity, minimal vibration,

outstanding dimensional accuracy

and unparalleled surface quality

LED lights turn on until

the printing is finished.

These lights let the user

know that the printer

is currently in use

The printer can detect when

the filament runs out during

printing and automatically

switch to spare ones,

Get consistent results with

magnetic spring steel film

to firmly embed the model

on the surface and remove

it fast when the job is done.

Plug & Play

Flexible

Build Plate

Quickly Replaceable

& Easy to Maintain

Modular electronic components are designed to minimize the damage of potential issues without creating the need for on-site technical service

LOOP 3D Core +

LOOP 3D Connect

HEPA - Carbon Filter

LOOP 3D

Calibration Check Tool

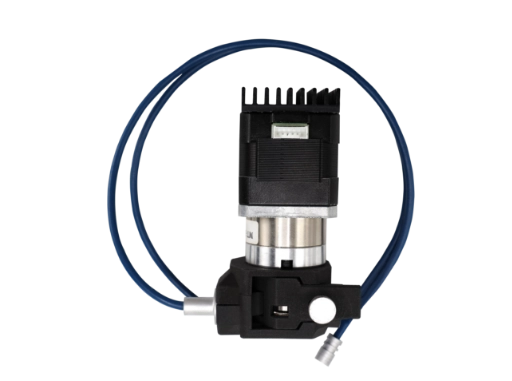

Extruder

LOOP 3D Printhead

LOOP 3D Core+ holds the controller board

and the motor drivers of LOOP PRO X

3D printer inside. From heating to cooling, positioning to filament extrusion,

every motion is controlled by this box.

LOOP 3D connect is the brain of

LOOP PRO X Series 3D Printers and holds a micro-computer inside. This box provides the cloud connection, UI and the touch screen controls.

Built-in carbon filter gets rid of unpleasant odour released during the 3D printing process. Thanks to the filter, LOOP PRO X Series 3D Printers can be used in offices and working environments.

It enables checking build plate calibration with high precision and minimal effort. Swap it with the modular printhead, and you are ready to test and set build plate calibration with a slight adjustment to the calibration screws.

LOOP 3D extruder is the part that is responsible for pushing the filament to the printhead with high precision and a superior strength. The extruder module comes with attached high-end filament tube for low friction, precision and high quality prints.

It is designed to be durable and swappable for long term use and easy maintenance while giving you the prints with the best surface quality. Thanks to the hardened steel noozle, printhead is able to print the hardest materials with ease.

Technical Informations

Technology & System

Physical Properties

Materials

Software

Advanced H-Bot mechatronics with

double linear guideway

Machine Interface

Connectivity

Mechatronics

Technology

Remote Monitoring

LOOP 3D CLOUD 2.0

Internet browser based

cloud slicing software

Open Material

System

Relative humidity (RH<%20)

with material

conditioning unit

Build Volume (up to)

Print Bed

Layer Thickness

Default Nozzle Diameter

Build Plate

Flexible - Magnetically attachable

spring steel with coating

Printhead

Chassis Material

External Dimensions

Printer Weight

Available Materials

Filament Size

Cloud Software (Default)

Fleet Management

Compatible File Formats

Offline Software

3rd Party Materials

Moisture Control

Carbon Fiber Reinforced PA6

Technical Informations