What is Chemical

Vapor Smoothing?

Advanced

Mechanical Properties

Reduction in

Bacteria Formation

Compatible with

FFF & SLS printing technologies

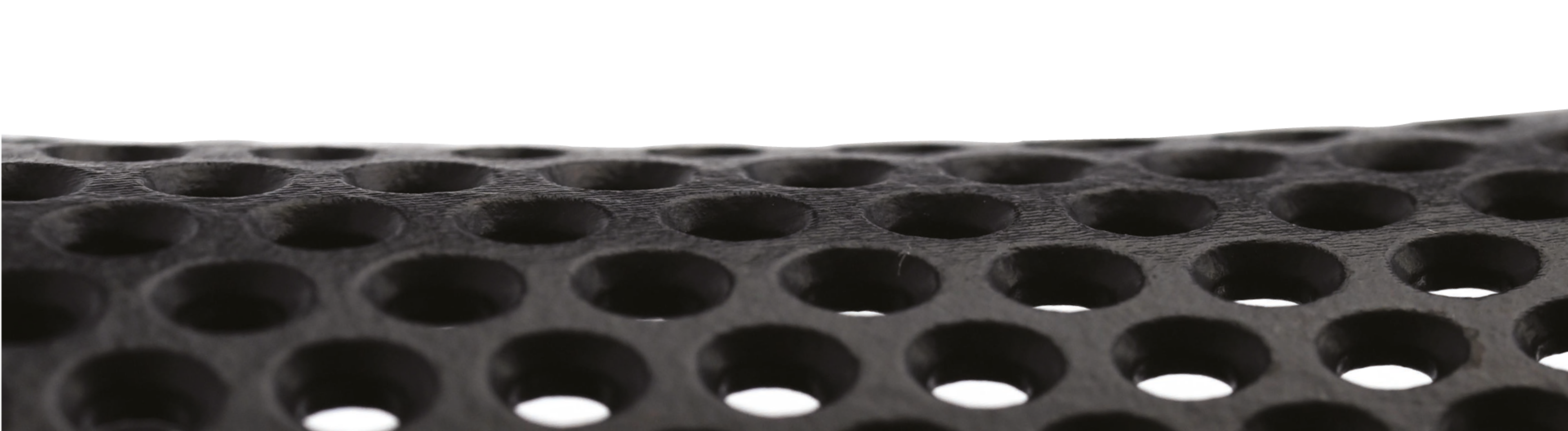

Post Pro chemical vapor smoothing is a physiochemical

process that improves parts’ surfaces. The process is not

limited to the visible surface only. The complex interior

gaps of polymer parts are also polished.

Thanks to high level of controllability, PostPro

technology provides repeatable results without any

deterioration in the mechanical properties of the part.

> Reduction in surface roughness

> Quality sealed surface

> Increased functionality

> The process provides parts with improved ultimate

tensile strength, take-up stress & elongation at break

> More stamina

> Increased thermal properties

> Process advanced in parts elongation at break

and provides ultimate tensile strength.

PA6 - PA11 - PA12 - ABS

Polypropylene - PC Arkema Rilsan Polyamide ® 11

Glass & Carbon Filled

Nanocomposites

Advantages of

Vapor Smoothing

What is Chemical

Vapor Smoothing?

Material

Compatibility

Post Pro chemical vapor smoothing is a

physiochemical process that improves

parts’ surfaces. The process is not limited to

the visible surface only. The complex interior gaps

of polymer parts are also polished.

Thanks to high level of controllability,

PostPro technology provides repeatable results

without any deterioration in the mechanical

properties of the part.

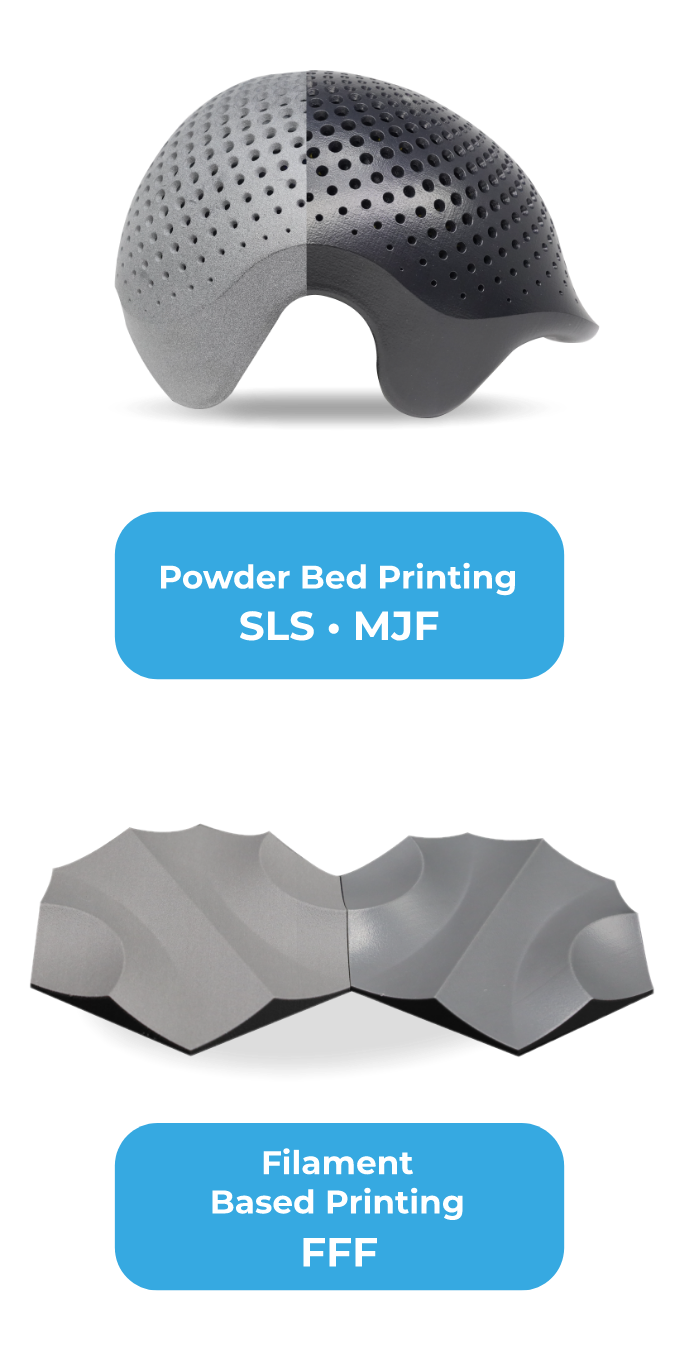

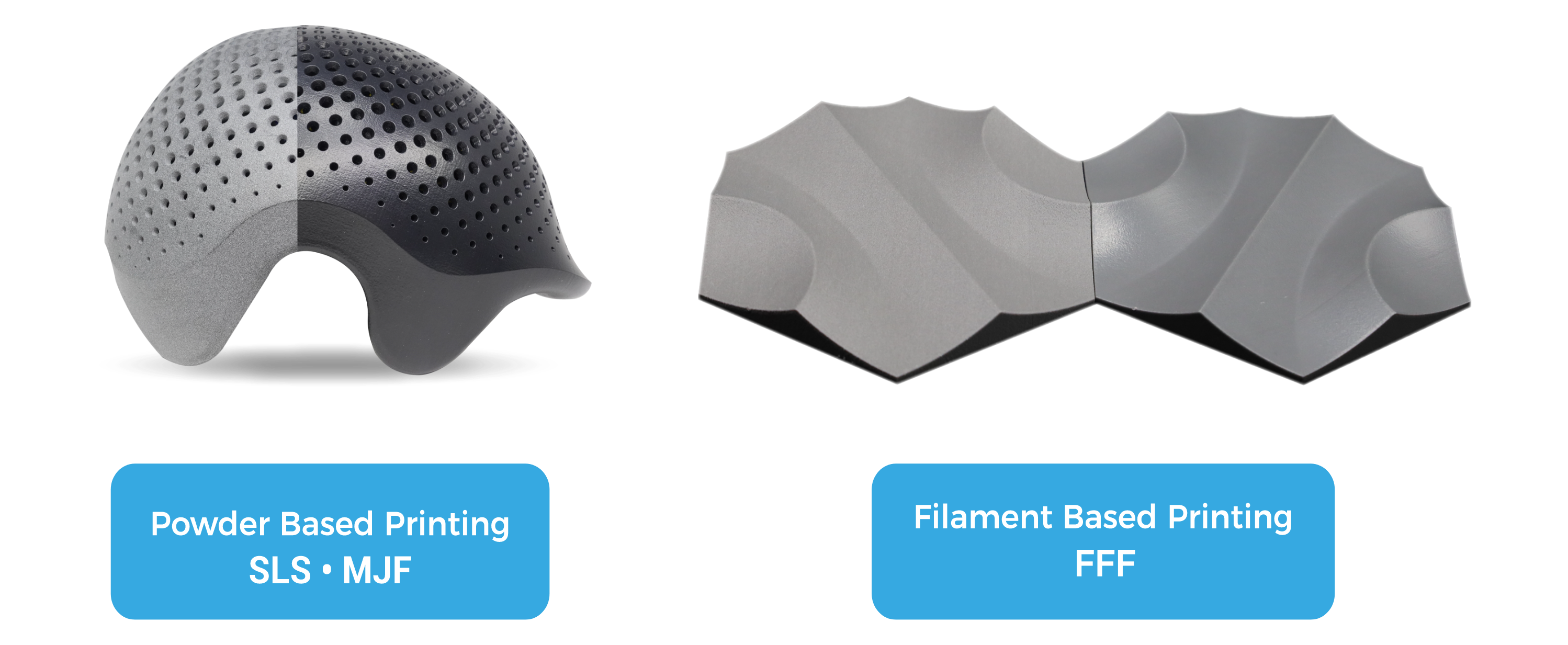

Compatible with powder bed and

filament based printing technologies.

> Reduction in surface roughness

> Quality sealed surface

> Increased functionality

> The process provides parts with

improved ultimate tensile strength,

take-up stress & elongation at break

> More stamina

> Increased thermal properties

> Process advanced in parts elongation at break

and provides ultimate tensile strength.

PA6 - PA11 - PA12 - ABS

Polypropylene - PC Arkema Rilsan Polyamide®11

Chemical

Vapor Smoothing

Compatible with

FFF & SLS

printing technologies

Advanced

Mechanical Properties

Sealing Against

Liquid & Gas

Reduction in

Bacteria Formation