Unsupported

Quick Print

High Volume

Mass Production

End-Use

Mechanical Parts

Complex

Geometries

Dimensional

Consistency

PA12 Black

Value

PA12 Black

Value

PA12 White

Value

PA12 White

Value

Advanced PA12-based polymer material, a wide variety of industrial suitable for applications.

Main Features:

> Balanced performance of thermal properties

> Excellent mechanical properties

> Good part surface ease of post-processing

> High oxidation resistance & low water absorption

Example applications:

> Mass production of functional parts

> Complex geometries

> High quality prototypes

> Versatile use for many industry applications

What is SLS

(Selective Laser Sintering)?

Advanced

Mechanical Properties

Reduction in

Bacteria Formation

Robust solution for

complex geometries

and precise dimensions

There are no support parts in SLS technology.

Powdered PA12 material is used as raw material.

Prints completed as a result of layer by layer sintering

of powdered polyamide material with laser are in the

quality of the final product in terms of dimensional

accuracy and strength.

SLS is suitable for the surface smoothing process

called chemical polishing and provides

plastic injection quality parts.

Advantages of

SLS 3D Printing

Dimensional

Consistency

Advanced PA12-based polymer material,

a wide variety of industrial suitable for applications.

Main Features:

> Balanced performance of thermal properties.

> Excellent mechanical properties.

> Good part surface ease of post-processing.

> High oxidation resistance & low water absorption.

Example applications:

> Mass production of functional parts

> Complex geometries

> High quality prototypes

> Versatile use for many industry applications

What is SLS

(Selective Laser Sintering)?

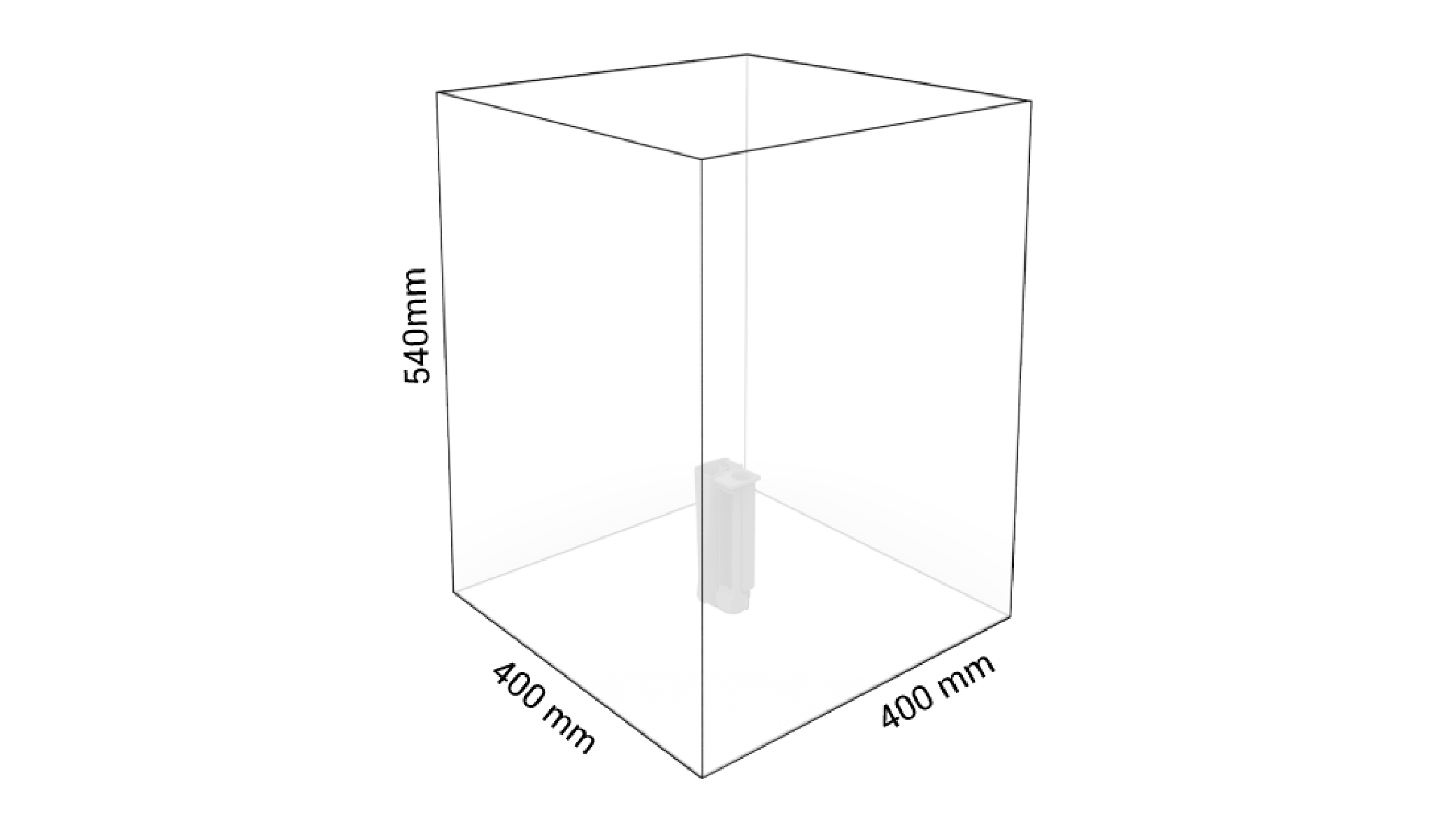

Technical

Specifications

There are no support parts in SLS technology.

Powdered PA12 material is used as raw material.

Prints completed as a result of layer by layer sintering

of powdered polyamide material with laser are in the

quality of the final product in terms of dimensional

accuracy and strength.

SLS is suitable for the surface smoothing process

called chemical polishing and provides

plastic injection quality parts.

Surface Treatment

Vapor Smoothing

Selective

Laser Sintering

Robust solution for

complex geometries

and precise dimensions

Unsupported

Quick Print

High Volume

Mass Production

End-use

Mechanical Parts

Complex

Geometries

PA12 Black

Value

PA12 Black

Value

PA12 White

Value

PA12 White

Value

Advanced

Mechanical Properties

Sealing Against

Liquid & Gas

Reduction in

Bacteria Formation

The process is not limited to the visible

surface only it also polishes the complex

interior spaces of polymer parts.