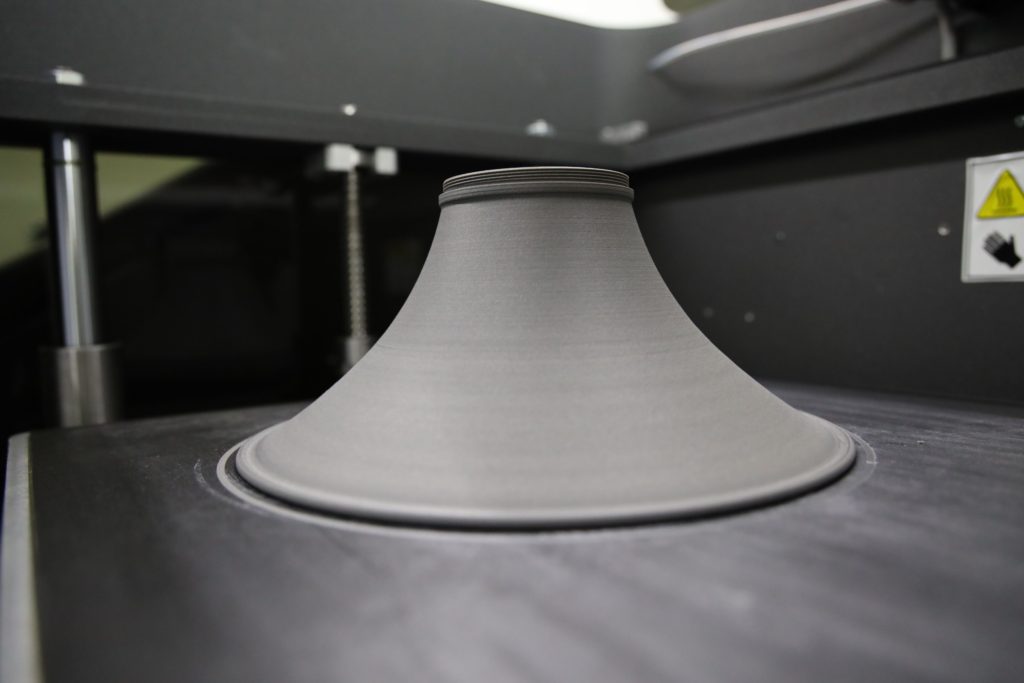

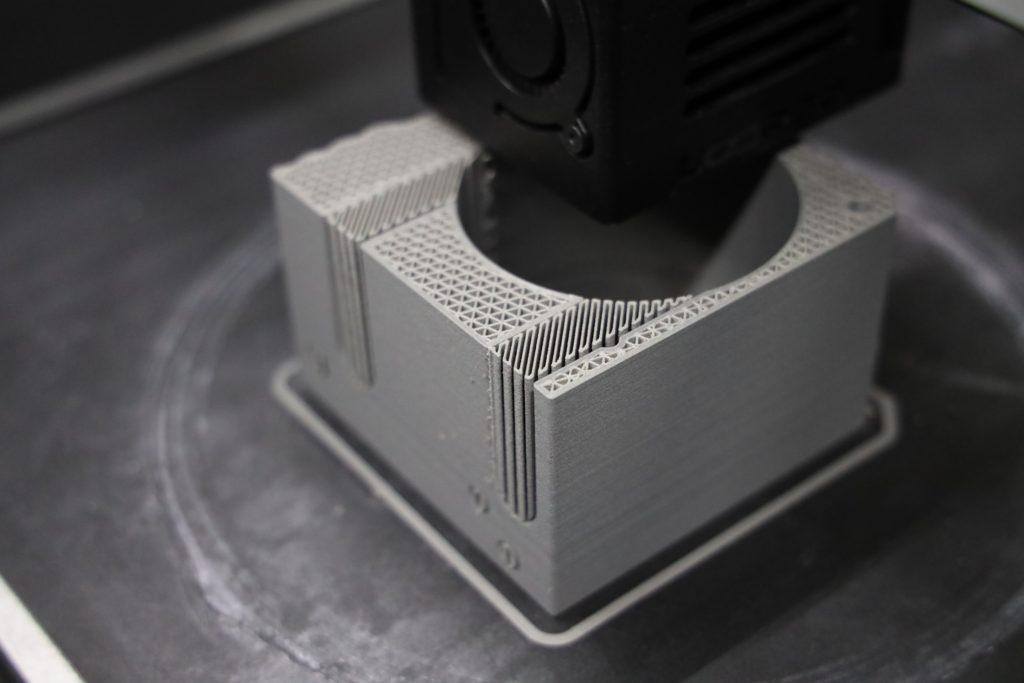

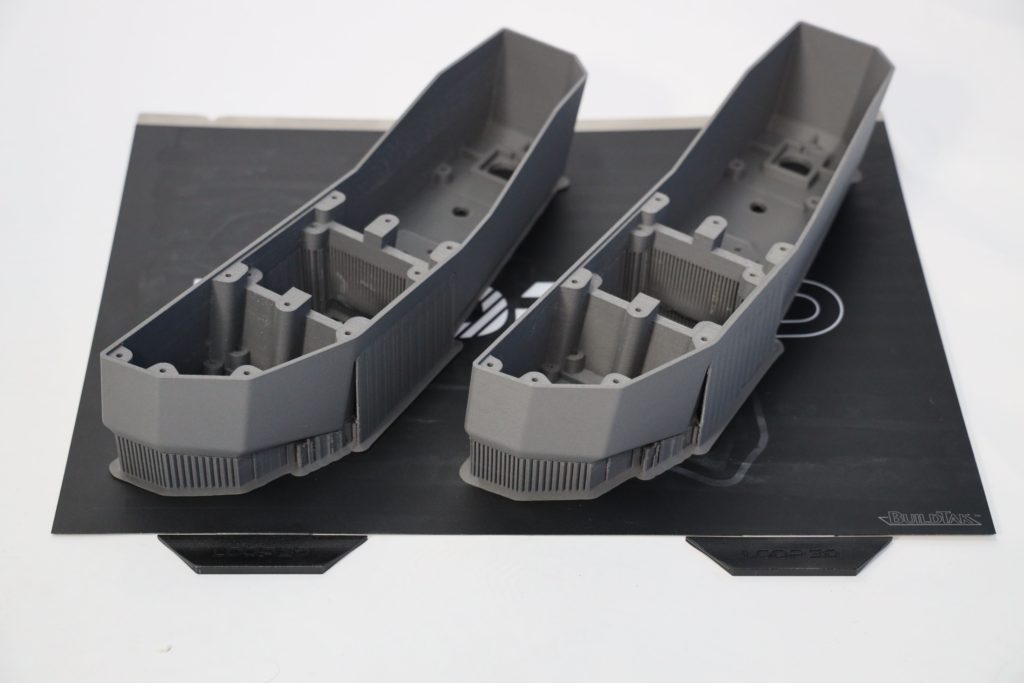

LOOP 3D enters the market with industrial grade DYNAMIDE® composite materials – reinforced with Glass Fiber and Carbon Fiber. Machine offers a large build space – 500 x 350 x 500 mm with flexible build plate made of spring steel for quick model removal, laser supported calibration, easy to service modular printhead, closed chamber with HEPA and Carbon filters and among all – LOOP 3D grants excellent surface quality with its dedicated materials, high model precision (layer thickness between 50-300 microns) and repeatability thanks to CNC-milled unibody aluminum casting which minimizes vibrations. Material Conditioning Unit, that can be found in the lower part of the printer’s cabinet, controls relative humidity in the chamber and prevents material degradation due to moisture.

Dedicated LOOP 3D CLOUD slicing software is designed to be user-friendly and multitasking. LOOP 3D offers connectivity to manage multiple units remotely from a single workstation and the printing progress can be monitored via livestream option. Offline version is also available. LOOP 3D CLOUD is more than just a slicer – it is project management tool which can track printer’s lifecycle, store all file formats connected to complex models or 3D projects. User can create space for multiple customers and teams as well as for safe remote printer access, where user decides about access levels for the team or LOOP 3D Remote Tech Support.

EMEA Sales Manager of LOOP 3D